Heat is the nemesis of electronic device reliability. Excessive operating temperatures can accelerate component aging, reduce conversion efficiency, and even pose safety risks. So, how do YHYadapter overcome this challenge?

Using Advanced Circuit Topologies

Traditional single-stage flyback topologies are limited in efficiency at high power le vels. To achieve more than 93% conversion efficiencies in the 150W range, YHYadapter use advanced two-stage architectures, such as PFC + LLC (Power Factor Correction + LLC Resonant). The PFC stage corrects the power factor to meet grid harmonic requirements, while the LLC stage enables Zero Voltage Switching (ZVS) for the power transistors, drastically reducing switching losses—a core technique for minimizing heat.

High-Performance Power Semiconductors and Magnetic Components

A. Gallium Nitride (GaN) or Silicon Carbide (SiC) Devices

Compared to traditional silicon-based MOSFETs, third-generation semiconductors like GaN offer lower on-resistance (RDS(on)) and faster switching speeds, significantly reducing both conduction and switching losses.

B. Low-Loss Magnetic Components

YHYadapter selects high-quality, low-loss ferrite cores and Litz wire for designing transformers and inductors to minimize hysteresis and eddy current losses during high-frequency operation.

Scientific PCB Layout

YHYadapter utilize thermal simulation software to optimize the PCB layout, strategically distributing major heat-generating components to avoid thermal hotspots. Furthermore, by using large copper pours and adding thermal vias, the PCB itself acts as part of the heat spreader, accelerating both lateral and vertical heat conduction.

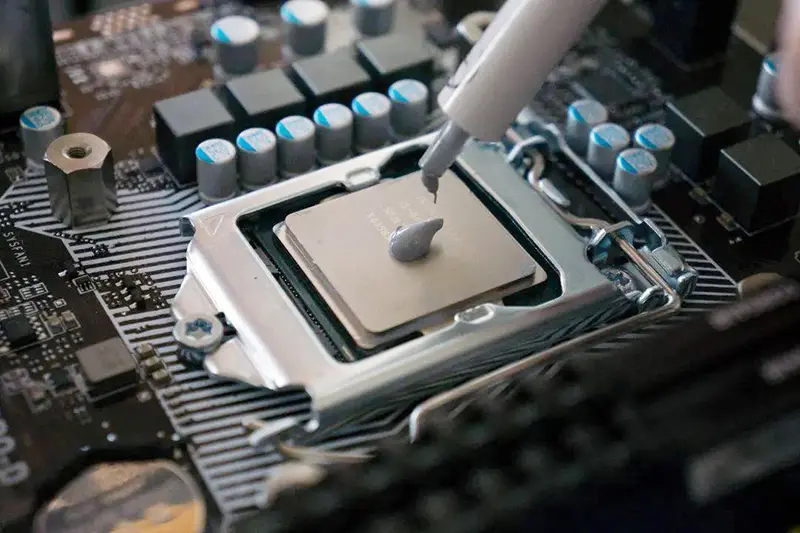

High-Efficiency Thermal Interface Materials (TIMs)

The microscopic air gaps between components and heatsinks or the enclosure are significant barriers to heat transfer. YHYadapter use high-quality thermal grease or thermal gels to fill these gaps. Their thermal conductivity is far superior to that of air, ensuring efficient heat transfer from the component surface to the cooling structure. For areas requiring electrical insulation, high-performance thermal gap fillers are used.

Enclosure Material and Structural Design

Compared to standard plastics, aluminum alloys offer superior thermal conductivity. YHYadapter prefer using unibody aluminum alloy enclosures and maximizing their surface area by incorporating fins, grooves, or micro-roughening treatments to significantly enhance natural convection and thermal radiation efficiency.

Innovative Thermal Coating Technology

In certain designs, YHYadapter apply high-emissivity thermal coatings, such as graphene, to the enclosure surface or internal heatsinks. This coating effectively increases the surface’s ability to radiate heat, boosting dissipation efficiency by an additional 5%-10% without altering the volume.

Conclusion: A Victory of Systematic Engineering

Achieving efficient thermal management in a compact 150W fanless power adapter is not the result of a single technological breakthrough but a complex, systematic engineering endeavor. It demands meticulous attention to detail and perfect synergy at every stage—from circuit topology and component selection, to PCB layout and TIM application, all the way to the final structural design.

This approach reflects YHYadapter team’s profound understanding and extensive practical experience in power electronics, material science, and thermodynamics. If you are seeking a fanless power solution that combines high performance with high reliability for your next-generation product, our team of experts is eager to collaborate with you to create a deeply customized solution.